This series of three

articles provides a broad

overview of today’s state

of the art for protecting

electrical workers against

electric arc thermal hazard.

•Part 1 addresses key factors

for further electric arc

PPE advancement.

•It also discusses the different

types of electric arc

and why this knowledge is

important for safety professionals

who perform arc

risk assessment

PS part 1 F3Gol_0717z.pdf

Adobe Acrobat document [919.4 KB]

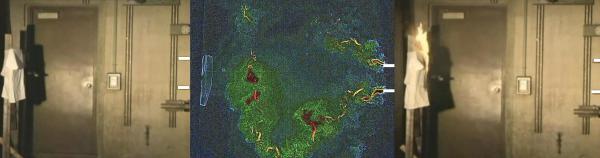

Cotton T-Shirt Ignition at 6.5 ft from arc electrodes, 8 kA, 30 cycles. Snapshots before, during, and afther the shot.

Focus on Electric Arc Flash

We should not neglect or underestimate the danger of two other types of electric arcs: arc in a low voltage enclosed switchbox and arc caused by personnel contact with energized parts. The first is also known as “arc-in-a-box” and the second is so called “tracking arc”.

Although, there is less total energy dissipated in low voltage arc-in-a-box, the accumulated thermal energy can escape only in one direction: through a mechanically failed or otherwise open door. Less emitted light energy is compensated by concentrated highly heated air flow.

Standardized test methods exist for two of four types of electric arc. There are currently no test methods for ejected and tracking arcs.

Arc Flash is the common name or nickname for an electric arc that takes place in electrical installation due to a dielectric insulation failure or a short circuit condition caused by human error or protective equipment failure/malfunction. From a physics prospective, an electric arc is an ionized conductive plasma column formed in the air between two electrodes; its temperature can exceed 5000°C.

Different types of arc have very different ways of delivering thermal energy.

Electromagnetic interaction between arc current and the current in proximate conductors generates mechanical force effecting arc behavior.

In open air an electric arc may be stationary or it may move along overhead lines and substation buswork. Stationary arcs build up heat energy around the fault spot until the fault is cleared. The time of exposure from a moving arc at any given spot along the line is very limited. Heat energy from a moving arc is only a fraction of stationary arc heat energy.

In open air, an electric arc can stay within the arc gap or it can be ejected by electromagnetic forces from the gap into the adjacent space. In the first case the thermal energy is distributed evenly in all directions. In the second, the arc and its thermal energy are ejected in one and only one direction. There can be a several times difference in heat energy received by personnel depending upon their position relatively to an ejected arc. In the example photographs, directionality of the arc resulted in non-FR Cotton T-shirt ignition at a distance of 6.5 ft away from the arc electrodes.

In the next photograph, the mannequin is even farther away (at 8 ft) from electrodes. Electromagnetic forces tend to shape the arc column as a circle with a 5-6 ft diameter. There was no ignition at this distance.